Polymer research has enduring effect on world: Part 2 — coatings and adhesions

As part of The University of Akron’s sesquicentennial celebration — honoring 150 years of our people, place and promises — we are hosting a “Celebration of Academic Excellence” to highlight the history and future of our many academic disciplines.

Professor Charles Knight introduced the world’s first rubber chemistry course in 1909 at Buchtel College, precursor to The University of Akron (UA) — providing intellectual fuel for the city’s high-powered rubber industry. In so doing, he also laid the foundation for what would become one of the world’s leading programs in polymer science and polymer engineering.

Today, the University’s polymer researchers — through innovations in health, advanced materials, biomimicry and sustainability — continue to elevate the region and improve the everyday lives of countless people. Here we're featuring research in coatings and adhesions.

A close look at a sticky situation

Dr. Ali Dhinojwala, H.A. Morton Professor of Polymer Science, co-authored a paper last year in Proceedings of the National Academy of Sciences (PNAS), in which he identifies the missing link between soft surface adhesion and the roughness of the hard surface it touches.

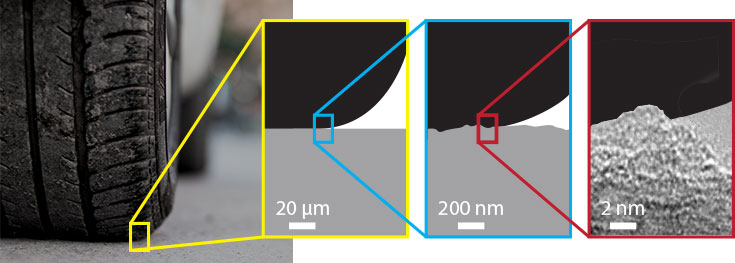

The traction of tires depends on the ability of the rubber to deform and make molecular contact with the surface. It is necessary to understand roughness of the road from something that we see with our eyes to all the way down to few nanometers. (Graphic prepared by Dr. Tevis Jacobs.)

Dhinojwala and coauthor Tevis D.B. Jacobs, assistant professor of mechanical engineering and materials science at the University of Pittsburgh, have used in situ microscopic measurements of contact size to unlock the fundamental physics of how roughness affects soft material adhesion.

All practical surfaces we encounter are rough, and some examples include sticking a tape on a wall, or a tire in contact with the road, or even rubbing our hands together. How roughness affects adhesion of soft surfaces has been an unresolved question.

The group developed a new approach using an electron microscope to measure roughness down to below the scale of a nanometer. One of the surfaces in this study appeared far smoother than two others when measured using conventional techniques; however, when measured down to the atomic scale, it proved to be the roughest of all. This small-scale roughness created a lot more surface area for the soft material to grip. The detailed understanding of the rough surface was the missing link that explained the predicted the surfaces’ adhesion behavior.

“This work that we published in PNAS provides us the first quantitative clue on how roughness affects adhesion and highlighted the importance of tiny bumps on the surfaces that are almost two thousand times smaller (nanometer) than the size of our hairs,” says Dhinojwala. “This study has helped advance our understanding of a problem that has not been resolved for decades.”

Leader in self-stratifying coatings

Dr. Mark Soucek

Dr. Mark Soucek, professor of polymer engineering, focusses his research on self-stratifying coatings. Many high-value items such as automobiles, bridges, aircraft and boats rely on multiple polymeric coatings (i.e., paint) for protection against wear and tear. Each coating has to be applied and cured separately, which results in a large carbon footprint and cost for each process.

Self-stratifying coatings combine two or more coatings processes into one coating process, thus making the manufacturing process less costly, and more sustainable. The function of two or more polymeric materials are retained by vertical phase separation during the film formation process, creating a film structure similar in function to a multicoating process.

The Soucek research group has been a leader in the field of self-stratifying coatings for many years. In fact, the first usable liquid-based coating system was co-developed at UA with a major automotive company. It was based on a typical automotive topcoat primer system. Later, the Soucek group used the same concept to develop pretreatment/primer/topcoat systems for the U.S. Department of Defense, focusing on naval coatings and coatings for ammunition and aircraft.

Soucek has previously been recognized with two major awards for his work in self-stratifying coatings: the the prestigious Roy W. Tess Award in Coatings by the American Chemical Society’s Division of Polymeric Materials: Science and Engineering (PMSE) and the Society for Protective Coatings Editor’s Choice Award.

Previous:

Next:

Media contact: Alex Knisely, 330-972-6477 or aknisely@uakron.edu.