UA researchers developed a new way to improve the performance of nonwoven polymer filters

Thin polymer fiber mats, in particular those made of nonwoven polypropylene fibers, are extensively used for medical and industrial filtration. The recent pandemic has increased the demand for the fabrication of protective masks. However, the nonwoven polypropylene filter has limitations in filtration efficiency and lacks advanced functionalities.

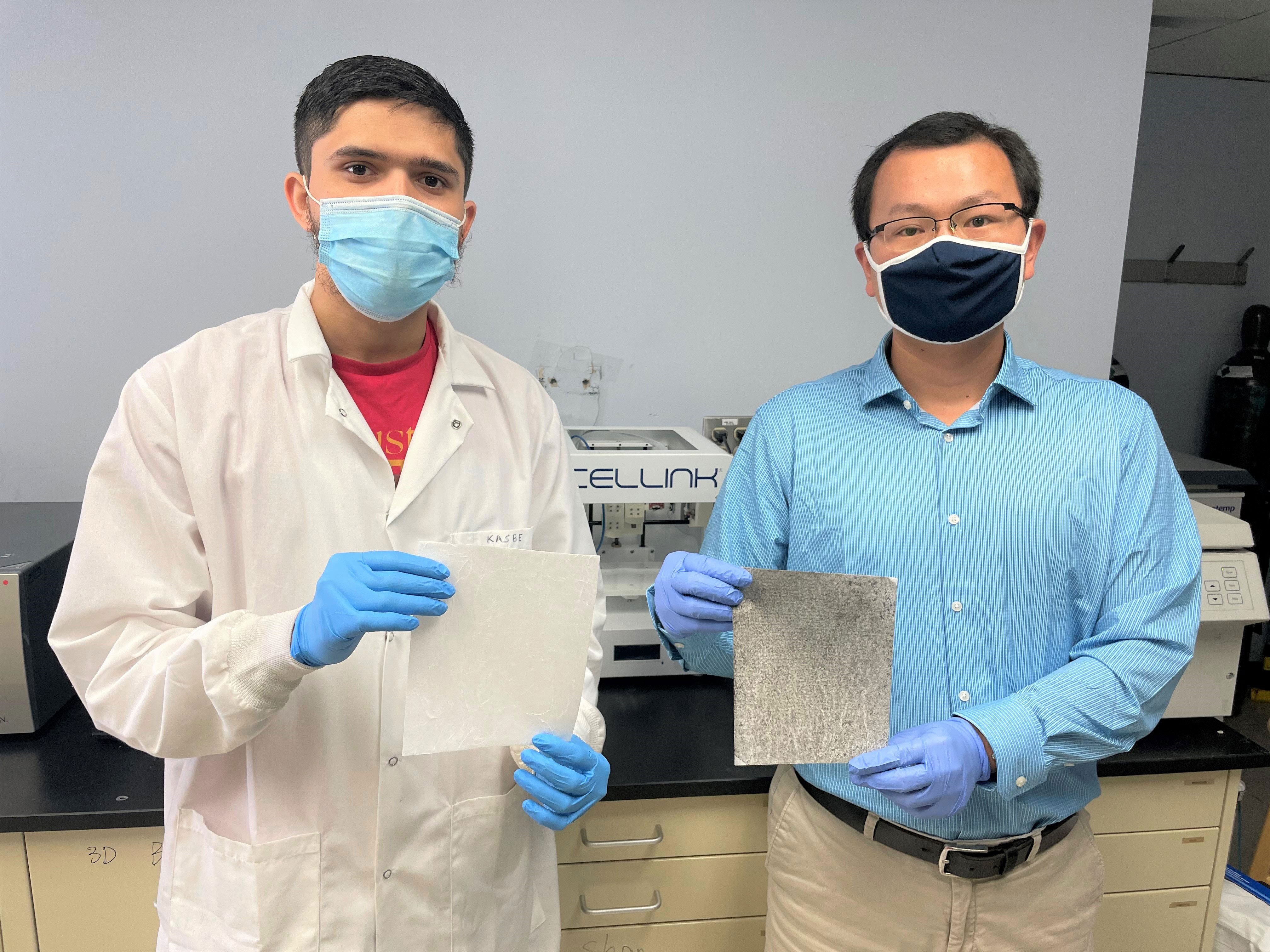

PhD student Pratik Kasbe (left) holding a nonwoven polypropylene filter; Dr. Weinan Xu (right) holding a polypropylene filter with the ultrathin hybrid coating.

Recent work from Dr. Weinan Xu’s lab in collaboration with Dr. George Chase at The University of Akron provides a simple and effective method to improve the filtration performance of nonwoven polypropylene filters and endow new functionalities. This work has been published recently in ACS Applied Bio Materials, and other authors include graduate students Pratik Kasbe, Harshal Gade, and Shan Liu.

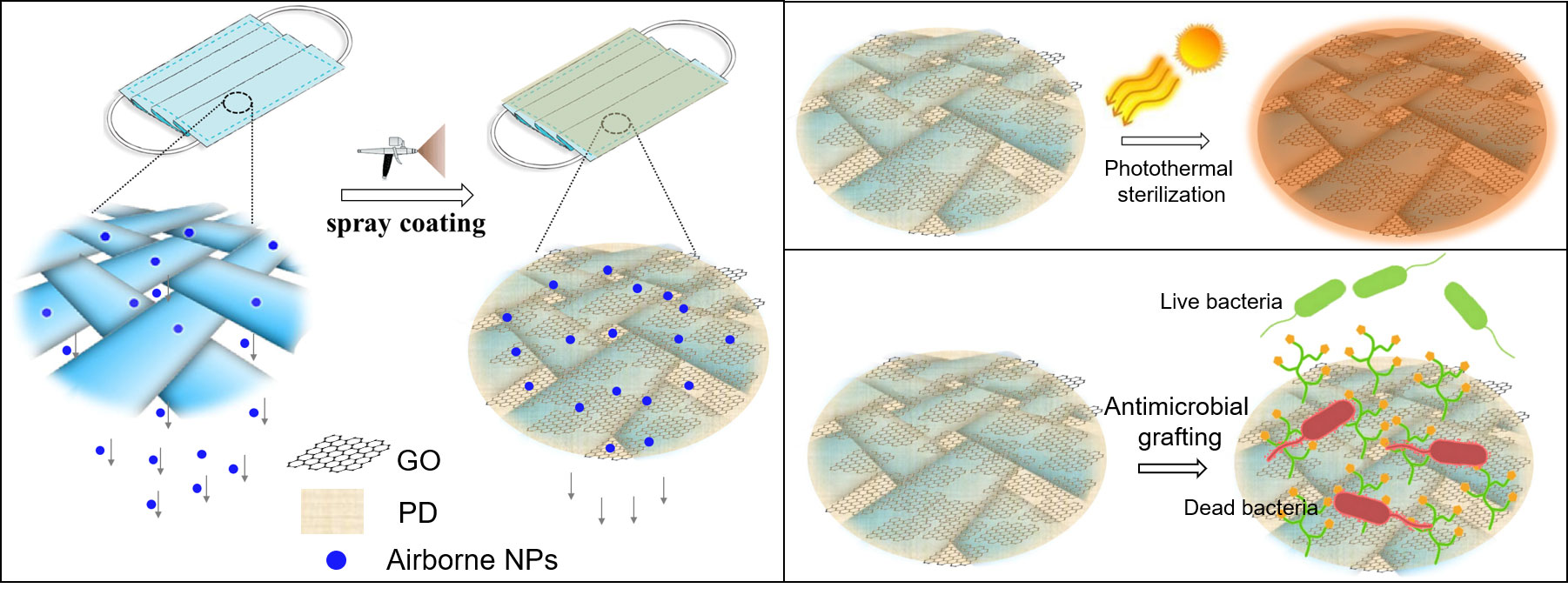

This new approach is based on the deposition of an ultrathin hybrid coating on the surface of polypropylene filters by spray-coating. The ultrathin hybrid coating is composed of atomically thin graphene oxide nanosheets and a bioadhesive polydopamine, with its thicknes less than 40 nanometers. The complementary properties and synergic effects of graphene oxide and polydopamine in the ultrathin coating improved the filtration efficiency of the PP filter by 20% with little change in pressure drop. The ultrathin coating also makes the surface of the filter more hydrophilic with higher negative charges. Importantly, the strong interactions between graphene oxide, polydopamine, and the filter surface endow superior stability of the hybrid coatings, which makes this technology safe to use in a wide range of applications, including protective masks.

Schematic of the deposition of the hybrid coating on a polymer filter by spray coating (left). The ultrathin hybrid coating endows photothermal sterilization (top right) and enhanced antimicrobial properties (bottom right) to the polymer filter.

Furthermore, the photothermal property of graphene oxide enables rapid temperature increase of the surface coated filter upon light irradiation for easy sterilization. Additional functional components such as antiviral agents or antimicrobial polymers can be chemically grafted to the surface of the hybrid coating, which provides highly desired antiviral or antimicrobial property to the polymer filters for their more effective protection against virus and microorganisms.