*** Please note, each row and course# listed below is a separate, complete course. ***

Polymers in Packaging

| Course# | Date | Time | Location |

|---|---|---|---|

| 141-1213 | 08/20/2025 - 08/21/2025 | 8:00 AM - 4:00 PM | Microsoft Teams |

| 141-1214 | 09/30/2025 - 10/01/2025 | 8:00 AM - 4:00 PM | Microsoft Teams |

| 141-1215 | 12/03/2025 - 12/04/2025 | 8:00 AM - 4:00 PM | Microsoft Teams |

| 141-1509 | 02/05/2026 - 02/06/2026 | 8:00 AM - 4:00 PM | Microsoft Teams |

| 141-1510 | 08/20/2026 - 08/21/2026 | 8:00 AM - 4:00 PM | Microsoft Teams |

| 141-1511 | 09/30/2026 - 10/01/2026 | 8:00 AM - 4:00 PM | Microsoft Teams |

| 141-1512 | 12/03/2026 - 12/04/2026 | 8:00 AM - 4:00 PM | Microsoft Teams |

Online Registration

CEU's: 1.6

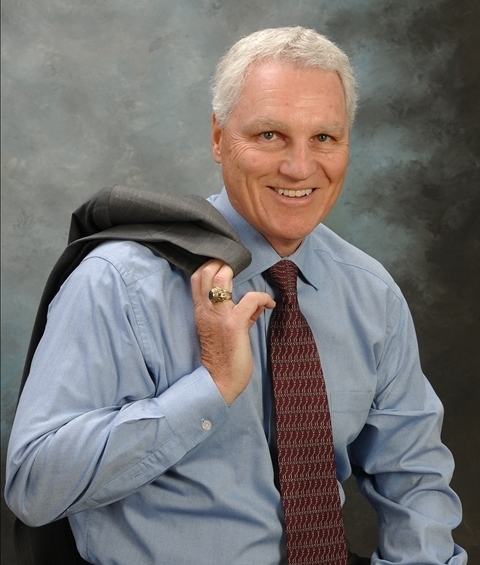

Instructor: Mr. Lawrence Dull

Course Overview

This two day course will present just enough polymer chemistry to allow the attendees to fully understand how polymers are built, how they are melted, how they are formed and why plastic packages behave the way they do. Along the journey we will cover all the basic plastic molding methods and discuss the common polymers used in packaging applications.

Online Course Requirements

We want you to have a great experience participating in our remote (online) courses, and for that, you’ll need the right equipment and internet connection.

Minimum needs are:

- A broadband internet connection that has at least a 2 Mbps upload and download speed.

- A computer (PC or Mac) that can support the latest web browser versions.

- At least 4 GB of RAM and adequate hard drive space.

- A microphone and a speaker.

- International Students: For virtual (online) courses, an additional fee will be assessed to cover the cost of shipping the professional binder (presentation slides), to your address. The cost of international shipping can be significant.

For more information, visit our Online Course Requirements webpage.

Instructor Biography:

Lawrence (Larry) Dull is a graduate Packaging Engineer (B.S. and M.S.) of Michigan State University. He has held positions with Eastman Kodak Company, Calgon Corporation (subsidiary of Merck and Company Inc.) and Syngenta Crop Protection Inc. (formerly Novartis, Ciba and Ciba-Geigy). He is currently President of Packaging Technology Associates Inc. and a founding partner of Packaging Knowledge Group, LLC. He is active in several industry and professional associations including ISTA (International Safe Transit Association), ASTM (American Society for Testing and Materials), and IoPP (Institute of Packaging Professionals). He holds nine U.S. patents in the field of packaging and has delivered numerous presentations and written numerous articles on packaging, packaging development and package testing and is an Honorary Professor at Hunan University of Technology in China. Larry is a past Chairman of the Packaging Task Group of RISE, past Chairman of the Chemical Packaging Committee of IoPP, past President and Chairman of IoPP and past Chair of the Sustainable Solutions Division of ISTA. He is an inductee in the PMMI Packaging Hall of Fame, the Michigan State University Packaging Hall of Fame and the IoPP College of Fellows and has been awarded the David LeButt Award for outstanding contribution toward continuing education in the field of packaging from ISTA.

Basic Polymer Chemistry

- Carbon

- Simple molecules/long chain molecules

- Molecular structure and behavior

- Molecular polarity

- Molecular weight

Polymer Types

- Polymer production

- Addition polymers

- Condensation polymers

- Thermoplastic polymers

- Thermoset polymers

Polymer Rheology

- Glass transition temperature

- Melt temperature

- Viscosity

- Melt flow

- Melt index

- Molecular weight distribution

Polymer Extrusion

- Plasticating extruder

- Molecular considerations during extrusion

- Crystallinity

Common Packaging Polymers

- Polyethylene

- Polypropylene

- Polystyrene

- Polyethylene terephthalate

- Polyvinyl chloride

- Polyvinylidene chloride

- Polyamide

- Polyvinyl alcohol and ethylene-vinyl alcohol

- Ionomers

Films

- Cast films

- Blown films

- Laminations

Molding Methods

- Thermoforming

- Blow molding

- Injection molding

- Injection/blow molding

- Injection/stretch blow molding

- Rotational molding

Package Performance Considerations

- Barrier properties/permeation

- Tensile strength

- Compression strength

- Impact resistance

Environmental Considerations

- Degradability

- Compost ability

- Current regulatory climate