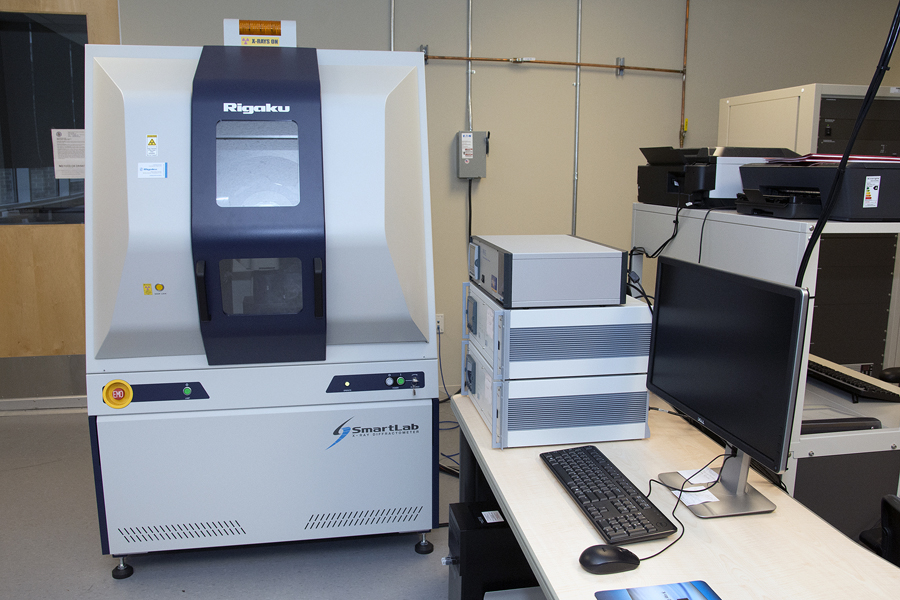

X-Ray Diffractometer (XRD)

Room 212 NPIC

Rigaku SmartLab X-Ray Diffractometer (XRD)

Background

X-ray Diffraction (XRD) is a nondestructive technique for characterizing crystalline materials or materials with some crystalline domains in them. In XRD analysis a collimated X-ray beam of known wavelength hits the tested sample. The crystalline parts of the materials exhibit three dimensional long range order of repeat arrangements of atoms (unit cells). The 3D unit cell ordering forms crystal lattices that diffract X-rays. X-ray diffraction occurs at specific angles with respect to the lattices spacing defined by Bragg’s Law and the result of an x-ray diffraction analysis is a diffractogram – a plot of diffraction peak intensities versus the angles of diffraction. The lattice spacing and crystal structure parameters can be determined from the plot. The response of amorphous, not ordered materials or domains in XRD is characterized by broad low intensity signals. If the material is completely amorphous no peaks will be observed in XRD.

XRD is unique in providing a wide variety of information on crystal structures, crystalline phases, preferred crystal orientations (texture), and other structural parameters such as crystallite size, percent crystallinity, strain, stress, and crystal defects. It is a must use characterization technique for almost all real world materials as it can provide valuable information for their degree of crystallinity. Diffraction patterns can be searched in large databases of patterns from known materials in order to identify/quantify the material phases present in a sample.

Applications

Wide angle x-ray diffraction (WAXS) in reflection and transmission geometries; nanomaterials, powders, alloys, corrosion studies, materials for tribological control, biomaterials, thin polymer films, thin film multilayers, patterned films; identification and quantification of the crystalline phase; determination of percent crystallinity in mixed crystalline/amorphous samples; thin films thickness measurements, measurement of average crystallite size, strain, or micro-strain effects; texture (preferred orientation) of crystallites; residual stress – lattice compression or expansion; High resolution characterization of thin metal, ceramic, polymer, and composite films; Identification of crystalline structure characteristics in very thin (nm) films and surface layers; characterization of perfection of in-plane ordering in functional polymer and composite films; determination of multilayer structure for films up to 400 nm thick; quantification of interfacial width between layers in multilayers or between coatings and substrate; quantification of interfacial roughness with angstrom level resolution; depth profiling of thin coating uniformity with 10 angstrom resolution; Determination of thin coating thermal expansion with angstrom resolution; Quantification of thin coating swelling with humidity

Specifications

X-ray diffraction and reflectivity system capable of characterizing bulk materials, powders, thin films, surface structures, at ambient conditions and at high humidity and high temperature

- Two theta range: 0 – 160 degrees (WAXS)

- X-ray generator

- Cu anode X-ray tube: 3 kW; Voltage: 20-60 kV, 1 kV step; Current: 2-60 mA, 1 mA step; X-ray wavelength: 1.54 Angstroms (Copper K alpha)

- Incident Optics

- Cross Beam Shaping Optics (CBO) with Parabolic Mirror: User selectable Parallel Beam and Bragg-Brentano optical configurations for asymmetric and symmetric scanning geometries.

- Parallel Beam Optics (Thin film characterization)

- Incident beam parabolic multilayer x-ray mirror compatible with all Parallel Beam optics including Ge channel-cut optics; Automated mirror control and alignment; Variable Incident Slit: 0.05 – 7.0 mm, 0.01 mm step; Height Limiting Slits: 2, 5, 10, and 15 mm

- Bragg-Brentano Optics (Powder diffraction)

- Variable Divergence Slit: 0.05 – 7.0 mm, 0.01 mm step; Height Limiting Slit: 2.0, 5.0, 10.0 mm; Soller Slits: 5° axial divergence

- Ge (220) 2-Bounce Incident Beam Monochromator

- High-resolution channel-cut incident beam monochromator for high-resolution parallel beam measurements of the crystal structure of highly perfect epitaxial materials

- Goniometer System

- SmartLab high-resolution vertical theta-theta goniometer system with open architecture design for horizontal sample mounting and measurement

- Hybrid pixel array detector for point, 1-dimensional, or 2-dimensional detection – fastest technology in the U.S. Ultra-broad dynamic range: 108 counts/s

- Humidity chamber for studies up to 300°C, and at high humidity

- Domed graphite sample hot stage for measurements at temperatures up to 1100°C

- SmartLab Guidance Software

- User friendly instrument control software selects optimal hardware configurations and provides fully automated optics alignment, sample alignment, slit and scan condition setting, and measurements setup

- PDXL Comprehensive Analysis Package with ICDD database

- Phase ID and search and match capabilities; Automatic data reduction and peak list reporting; Automatic background elimination; Automatic and/or manual peak finding; Degree of crystallinity determination