There have been immense changes in how plastics are viewed over the last 20 years. Mounting pressures to end single-use plastic, recycle more efficiently, and reduce the amount of plastic waste has led to nation- and world-wide action through legislation and business opportunities. Researchers in the School of Polymer Science and Polymer Engineering (SPSPE) are addressing emerging challenges in sustainability through collaborative research efforts, education, and outreach. Our junior faculty are leading several thrusts in this direction. Interim Director of SPSPE Ali Dhinojwala commented “We at The University of Akron started the first rubber chemistry class 130 years ago and now our polymer program has invested in faculty hires and curriculum development to address our societal needs to build a more sustainable future”. From advancing degradable plastics to improving material recovery from recycling our research, here are some of the recent sustainability highlights from our faculty.

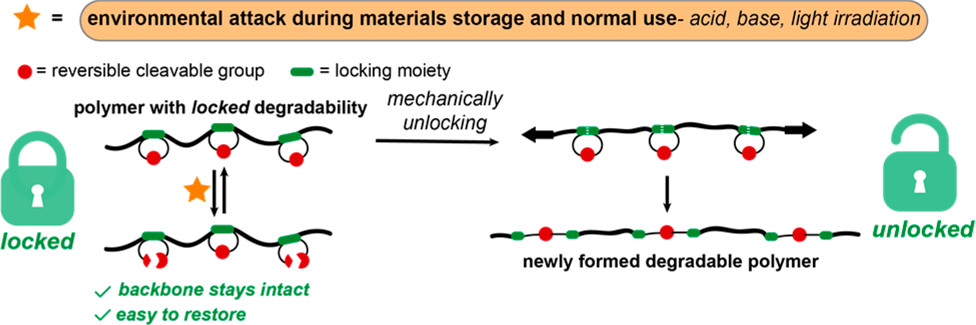

In January, assistant professor Junpeng Wang published a polymer design which could interconvert between a polyolefin backbone and degradable polyester (J. Am. Chem. Soc. 2020, 142, 2100-2104). “Polymers that can degrade in response to external stimuli are desirable for a variety of applications, including removable coatings, recyclable materials, and repairable electronics,” says Prof. Wang. “A locking moiety will maintain the backbone integrity and mechanical properties of the polymer during storage and normal use of the materials. When degradation or depolymerization is needed, the locking moiety can be unlocked to enable stimuli-responsive degradation or depolymerization."

Carbonfiber reinforced plastics (CFRP) are essential materials in the many industrial sectors due to their lightweight and high strength. They offer immense energy savings but are challenging to recycle, and recovery of the expensive carbonfiber is virtually impossible. Emerging materials termed “vitrimers” are exciting alternatives that exhibit the mechanical properties of conventional crosslinked polymers but behave as processable thermoplastics – addressing both the recyclability and recoverability of the CFRPs. In September, assistant professor Fardin Khabaz published work in Macromolecules (doi: 10.1021/acs.macromol.0c01423) where the rheological properties of vitrimers is modelled using a hybrid molecular and Monte Carlo approach. "The proposed methodology incorporates timescale of bond exchange in different regimes of deformation (i.e., glassy, rubbery, and viscoelastic liquid) and connects the local microstructure and dynamics of the crosslinks to the macroscopic properties of these networks. “Prediction of thermodynamics, rheology, and mechanics using this method provides mechanisms for observed phenomena in experiments of these self-healing polymers, and presents routes to inverse design of vitrimers to meet engineering specifications,” added Prof. Khabaz. CFRP is going to play an important role in aerospace and automobile industries and our colleague, Professor Miyoshi is studying the formation of carbon fibers using solid-state NMR with the goals to make this process simpler and less energy intensive (Macromolecules, doi/10.1021/acs.macromol.9b01906).

This fall, a collaboration between Polymer Science and Polymer Engineering secured $138,000 in research funds from the CenTire NSF research center to study the enhanced crystallization of recycled PET materials. Assistant professor James Eagan (PS) in collaboration with professors Kevin Cavicchi and Sadhan Jana (PE) are studying the purification of PET materials with the intent to convert bottle grade PET into technical grade PET fibers for tire-cord applications. “Bottle grade PET is low viscosity and contains additives to break up crystallinity and provide clear, blow-moldable beverage bottles. These materials are not suitable for processing or repolymerizing into high viscosity, highly crystalline reinforcing fibers. Our approach is a novel purification procedure to allow recycling plastic bottles into tire-cords hopefully improving the lifecycle of polyester plastics,” said assistant professor James Eagan.

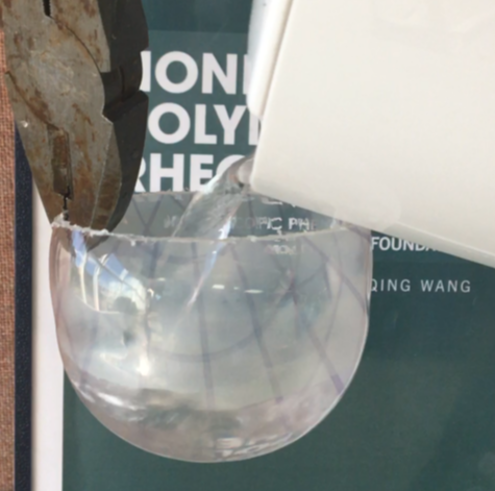

PLLA is a promising material for displacing conventional non-degradable petroleum derived plastics. Ongoing work from Professor Shi-Qing Wang’s group has elucidated how and why PLLA is brittle, answers which are now manifesting in ductile PLLA with high deformation temperatures. “The impact of our new understanding could finally stimulate the PLA market to grow exponentially,” said Wang.

In 2020 two undergraduate classes focused on polymer sustainability were offered in the Williams Honors College by our faculty. Assistant professor Ruel McKenzie taught a course on “Polymers and the Environment”. Prof. McKenzie described the objective of the course “was to discuss in a holistic manner: the extent to which polymers have enabled societal transformations, attempt to raise a collective awareness detailing the resultant ecological ramifications of polymer production, highlight some of the advances in mitigating the ecological impacts and to explore paths for a more sustainable coexistence with these materials.” In the honors college, undergraduates participate in discussions with global thought leaders, an interaction Prof. Mckenzie says help undergraduates “gain specific insight and a human perspective on the knowledge gained and pathways explored to resolve the emergent and pressing issues of polymers and the environment.” Additionally, this fall a course focused on “Sustainable Plastics” is being offered to undergraduates and invited lectures from experts in recycling, life-cycle analysis, and UA alumni working on renewably sourced polymers.

A team of UA professors from the School of Polymer Science and Polymer Engineering, the art school, and the college of arts and sciences are establishing outreach programs with local schools St. Vincent-St. Mary High School and the LeBron James IPromise School. These programs are focused on collecting plastic waste and recycling them into artistic creations from the student’s imagination. The undergraduate students in the College of Engineering and Polymer Science have started the Zips Precious Plastics (ZPP) initiative on campus to explore ways to sort and reuse plastic waste generated on campus.

The above efforts and events are only a glimpse of how the School of Polymer Science and Polymer Engineering are engaging in sustainability. Ongoing research is focused on CO2-based polymers, compatibilizers for recycling, renewable energy storage and generation, and many more.

Written by Dr. James Eagan | 330-972-7510 | eagan@uakron.edu.