Projects

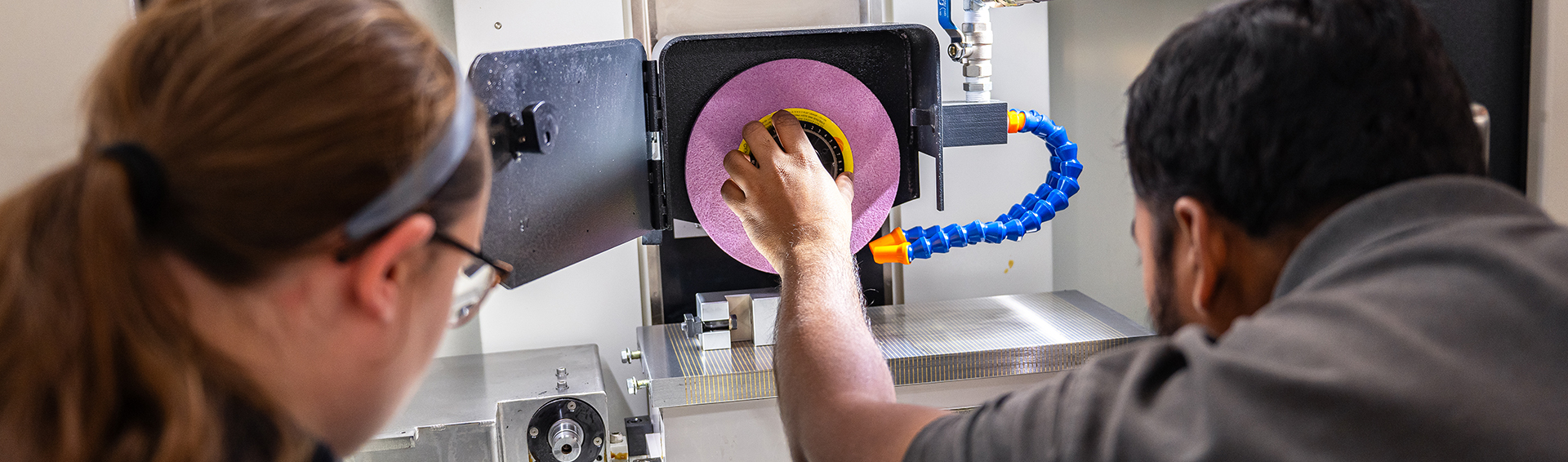

Centerless Grinding of Silicon Nitride (Closed Project)

Principle Investigators: Dr. Manigandan Kannan and Dr. Craig Seidelson

Project Summary and Goals: Silicon Nitride (Si3N4) material is one of the toughest technical ceramics available. Over the years it has been successfully used in a wide variety of applications ranging from aerospace to automotive engine components to roller bearings. Unfortunately, the extreme hardness of this material equates to greater brittleness which makes grinding very difficult. On the one hand, enough material must be removed from the surface to cut through porosity and inclusions inherent to the manufacture of this material. On the other hand, when grinding Si3N4 it has a propensity to crack and nick rendering parts made from it useless. The aims of this work are three-fold. One is a better understanding thermal range over which cracks form during the grinding of Si3N4. Two is to use this data to determine if it is possible to extrapolate a maximum temperature under which crack depth does not exceed chip thickness. And three is to use chip morphology data to develop an equivalent chip thickness-based grinding model.

Study and Design of Machine Learning Techniques for Quality Assessment of Grinding Processes (Closed Project)

Principle Investigator: Dr. Hamid Bahrami

Project Summary and Goals: The relationship between various grinding parameters and the quality of the grinding processes is complex in nature and difficult to model precisely. Machine Learning (ML) is an enabling technology that can be effectively used in modeling complex processes and extracting correlations between various system parameters. In this project, the aim is to study the ML-based modeling of surface roughness parameters and the grinding forces based on the knowledge of grinding parameters, such as wheel speed, feed rate, depth and width of cut, as well as the temperature and acoustic emission (AE) signals.

In-Process Inspection of Restricted spaces with High Reflective Surfaces using Miniature Confocal Chromatic Sensors with Radial Beam (Closed Project)

Principle Investigator: Dr. Nariman Mahabadi

Project Summary and Goals: On-machine in-process measurement has shown remarkable achievements in ultra-precision manufacturing since it increased inspection efficiency, improved machining accuracy, and increased automation level. However, inspection for precision machined interior surfaces with highly reflective fine finishes remains a challenge in the machining process. To address this challenge, this work aims to explore a unique miniature confocal chromatic sensor with radial beam which has shown significant improvement in real-time high-resolution profile measurement of restricted spaces with highly reflective surfaces.

Influence of manufacturing processes residual stresses on hydrogen embrittlement catastrophic failure mechanisms of additively manufactured stainless steel components (Closed Project)

Principle Investigator: Dr. David M. Bastidas

Project Code: Additive-2022-MP-1

Project Summary and Goals: The goals and deliverables of this project are 1. Reveal the failure mechanisms of hydrogen embrittled AM stainless steel components, 2. Unraveling the influence of residual stresses due to manufacturing and working condition of the integrity of AM stainless steel components, and 3. Development of a computational model able to predict the durability over the service lifetime of AM components under the influence of hydrogen assisted cracking environment. Research tasks and methodologies will include mechanical and corrosion testing in acid medium environments, mimicking an environment where hydrogen embrittlement is being promoted. In-depth surface characterization as well as throughout internal inspection by micro-CT will be done to disentangle the effect of hydrogen trapping inside the pores created during AM. A computational model will be used to learn the preferential sites and conditions leading to the loss of resilience of the AM stainless steel components.